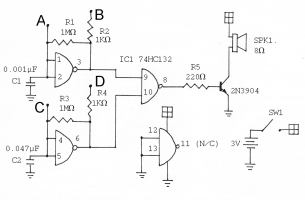

Capacitor. A device that can store an electrical charge.

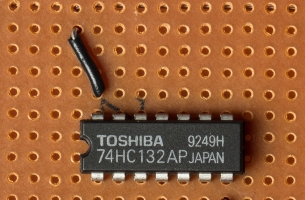

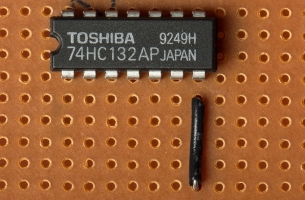

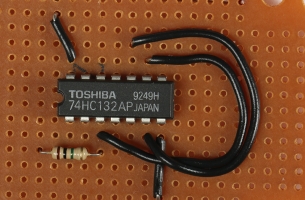

Chip. Informal name for an integrated circuit.

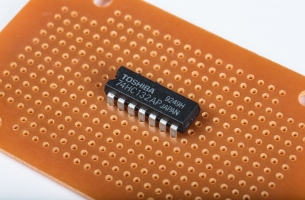

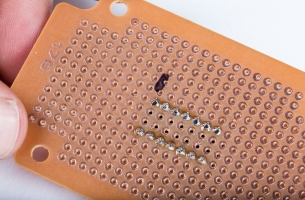

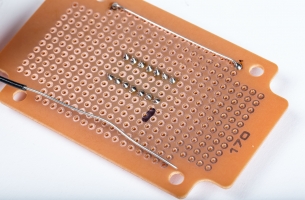

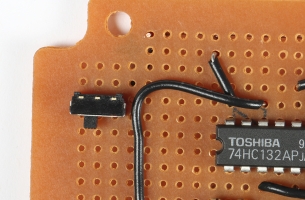

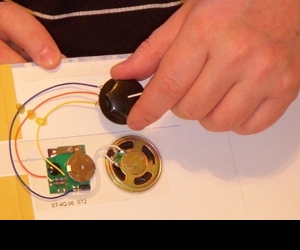

Circuit Board. A board, usually fiberglass, perforated with holes to mount components in.

Conductive Thread. A cotton or polyester thread that is uninsulated and incorporates metal strands.

Digital. A circuit that only has two voltage levels, high and low, represented by the binary digits 0 and 1.

Farad. A measure of capacitance, named after Michael Faraday.

Ground. The common point in a circuit, where all signals return.

Hookup Wire. Wire that’s already out the door when you wake up. It’ll maybe send you a text sometime.

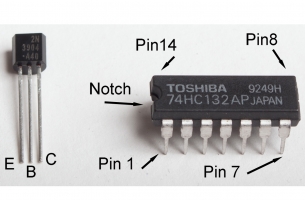

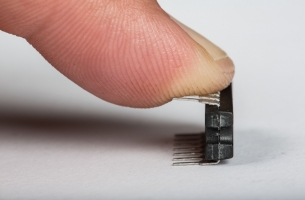

Integrated Circuit (IC or chip). A component containing an entire electronic circuit fabricated on a tiny piece of silicon.

Kilo. A prefix meaning 1000. One-kilo ohm, usually written 1k-ohm, or 1 kΩ, is 1000 ohms.

Leads. (Pronounced leeds). The wires protruding from an electronic component such as a resistor.

Logic Circuit. A digital circuit.

Logic Probe. A device that can show levels in a digital circuit.

µ. The Greek letter mu, used to denote micro, i.e., 1/10000000. 1µF is read as “one microfarad” and is equal to one millionth of a farad.

µF. Microfarad. See above.

Ohm. A unit of electrical resistance, named after Georg Ohm and designated by the Greek letter omega (Ω).

Oscilloscope. A device that can show a real-time graph of voltage over time.

Ω. The Greek letter omega, used as a symbol for ohm.

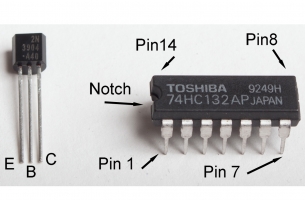

Pins. The connection points of a chip, also known as legs.

Resistor. A device that limits electrical current.

Soft Circuits. Circuits made with conductive fabric components.

Transistor. A device that controls the flow of electricity.

Wearables. Short for wearable technology, a broad category that includes textile electronics such as this project.